At SKF, we have a long history of working with industrial sustainability. It is an integral part of what we do every day. We strive to create engagement throughout the business, not only by implementing sustainability on a strategic level but also by encouraging the ideas and grassroots projects initiated by our people around the world.

SKF provides reliable rotation by combining hands-on experience in over 40 industries with in-depth knowledge across the SKF technology areas: bearings and units, seals, services, and lubrication systems. Our products and solutions help customers improve safety, reduce friction, improve process efficiency, reduce waste and use of material, extend service life, and achieve other sustainability benefits. We also contribute to the growth of transformative cleantech sectors, such as the renewable energy industry and electric vehicles.

A Holistic Approach to Sustainability

Our commitment to creating products and solutions that help customers transition to a more sustainable world is evident in our comprehensive sustainability strategy and innovative technologies. SKF has set ambitious targets to combat climate change, including decarbonizing all sites by 2030 and achieving net-zero greenhouse gas emissions in our supply chain by 2050. This means collaborating not only within the business but with other stakeholders in society on the same journey. Recently, we announced that SKF has secured EUR 430 million in financing from the European Investment Bank (EIB)

with a tenor of up to ten years. The funding will support SKF’s research and development (R&D) to increase the focus on high-growth segments and accelerate the design and development of enabling technologies, particularly for the green transition and sustainability.

Innovative Products for a Sustainable Future

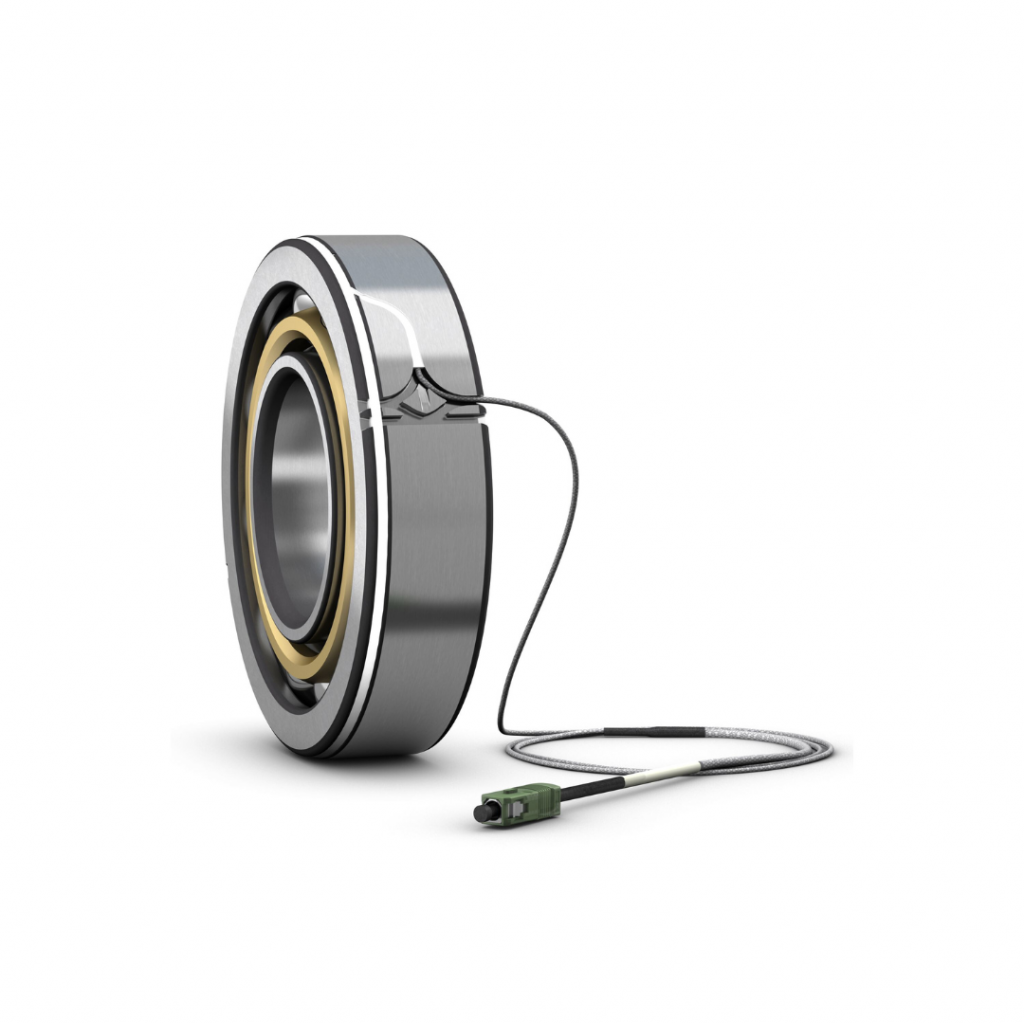

One of SKF’s primary contributions to sustainability lies in the development of clean technology solutions for industrial transformation and in developing more and more of our products to become lighter, more efficient, longer lasting, repairable, and, ultimately, recyclable. This, in turn, helps our customers reach their goals for sustainability and growth. For instance, SKF’s energy-efficient bearings and advanced lubrication systems help industries lower their carbon footprint and improve operational efficiency. SKF has also invested further in ceramic technology and products enabling several cleantech areas, such as wind, electric vehicles and railway. SKF’s R&D focus on technologies and products for renewable energy generation, electric vehicles and railway applications will help to improve the performance of current cleantech technologies as well as enable new cleantech innovations. SKF aims to support the growth of these technologies and industries, which, in turn, will help to reduce environmental impact on a large scale. Additionally, SKF’s R&D related to improving product and application performance in, for example, friction, service life and reliability will help to reduce the environmental impact in terms of savings in energy use and material use and avoided greenhouse gas emissions.

& Technology Development at SKF

One of the examples is how SKF uses applied AI technology for remanufacturing. Remanufacturing is a key element for a circular economy, allowing to keep materials and products in use longer and thereby reducing both cost and environmental impact. An important step of the remanufacturing process is to make a visual inspection of the received bearings, to identify potential damages and evaluate options for remanufacturing. SKF has developed a new app for bearing damage detection and classification. This app includes applied AI technology to improve visual inspection and support digitalization and standardization of remanufacturing data flow. Thereby, the remanufacturing operations become faster, more efficient and intelligent.

Collaborating for Impact

SKF recognizes that achieving sustainability goals requires collaboration. By focusing on the entire value chain, SKF ensures that its sustainability efforts extend beyond our own operations to include the broader industrial ecosystem. SKF has been cooperating extensively with educational institutions and universities to advance bearing technology, including tribology, sensor technology, and product life cycles, aiding the exploration of new and sustainable solutions.

Supporting the Circular Economy

SKF recently launched the SKF Circularity Framework, titled “Re-Imagine Circularity for a Better Tomorrow,” which is a strategic blueprint aimed at transforming SKF’s business operations and offerings from a linear to a circular model. This framework provides clear direction to the organization, fostering a unified vision and purpose-driven transformation that integrates sustainability across all aspects of the value chain. By focusing on eliminating waste, optimizing resource use, and promoting innovative circular solutions, SKF seeks to minimize environmental impact while maximizing value for customers and stakeholders.

The way forward

SKF has had a clear focus on sustainability since the early 2000s. In fact, SKF’s focus on sustainability is not just about meeting regulatory requirements. It is a fundamental part of the business strategy and a reflection of the commitment to creating a better, more sustainable world. Through innovative products, collaborative efforts, and a holistic approach to sustainability, SKF is uniquely positioned to contribute to helping industries transition to greener practices and pave the way for a more sustainable future.